Which Is Better: Buying New Overhead Crane v.s. Used Overhead Crane?

Buying old industrial equipment can give a variety of benefits for a startup or rapidly developing business without breaking the bank. Purchasing used equipment such as forklifts, CNC machines, lathes, mills, or machine presses can expand your manufacturing capacity, resulting in increased productivity, enhanced product design, and new growth opportunities.

An used overhead crane may appear to be the ideal option for material handling demands for business owners who are constrained by an equipment budget or looking to save money. However, not all industrial machinery, particularly overhead travelling cranes, can be simply converted from one use to another.

To help with light-duty production, assembly, or fabrication, an used jib overhead crane, workstation overhead crane, or portable gantry overhead crane could be adapted into a smaller shop. Bridge overhead cranes and gantry overhead cranes, on the other hand, necessitate precise engineering, therefore it might be difficult to obtain used overhead crane equipment that:

- Matches the original application's duty cycle to your lifting application;

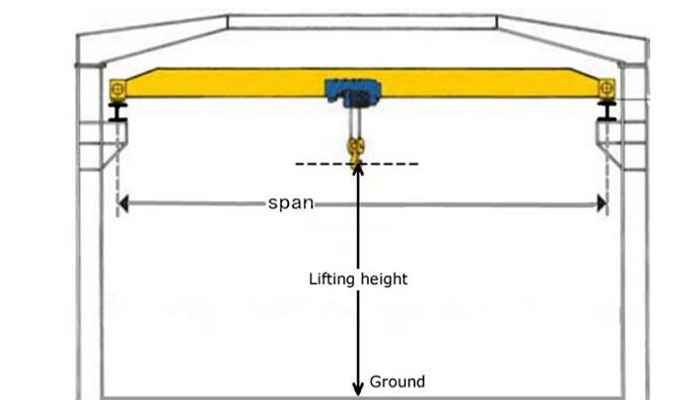

- Meets your building's span, lift height, and runway requirements

- Installs and supports within the constraints of your current building's structure.

- Current safety rules and industrial design standards are met (CMAA, OSHA, ASME, etc.)

We can design and build world-class overhead travelling crane systems, from light-duty economical overhead cranes to large-capacity, high-duty cycle overhead cranes, thanks to our 34 years of experience.

Our engineers and project managers work with customers of all levels of experience when it comes to purchasing an overhead travelling crane system. We're frequently asked if it's safe to install an used overhead crane and, if so, what concerns you might run into down the road. We'll take a look at the benefits and drawbacks of buying and owning an used overhead crane system in this post.

European Standard Suspension Single Girder Overhead Crane

Lifting capacity of single girder overhead crane: 1ton,3 ton, 5 ton to 10 ton

Span ofsingle girder overhead crane: 3-15 m

Lifting height of single girder overhead crane: 3-100 m

Suspension Single Girder Overhead Crane Chinese type

Lifting Capacity of Single Girder Overhead Crane: 0.5ton, 3 ton, 5 ton to 10 ton

Span of Single Girder Overhead Crane: 3m to 31.5m

Working Class of Overhead Crane: A3 to A5

FEM / DIN Top running Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 3.2ton, 3 ton, 5 ton 10 ton ton 16ton

Span of Single Girder Overhead Crane: 7.5m to 28.5m

Working Class of Overhead Crane: A5

Chinese Style Top Running Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span Length of Single Girder Overhead Crane: 7.5m-28.5m

Working Class of Overhead Crane: A3, A4

Explosion Proof Single Girder Overhead Crane

Lifting Capacity of Single Girder Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span of Single Girder Overhead Crane: 7.5m to 28.5m

Working Class of Overhead Crane: A3, A4

Partial Hung Low Headroom Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Single Girder Overhead Crane: 7.5m to 22.5m

Working Class of Overhead Crane: A3, A4

Low headroom Hoist Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Single Girder Overhead Crane: 7.5m to 22.5m

Working Class of Overhead Crane: A3, A4

Ladle handling Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 1ton, 3 ton, 5 ton, 10t

Lifting Height of Single Girder Overhead Crane: 6~18m

Working Class of Overhead Crane: M5

Where can you purchase an used overhead cranes?

You must first know where to hunt for an used overhead crane before you can purchase one. Some solutions are better than others, just like anything else, and you should always do your research before purchasing used overhead crane or hoist equipment.

Used overhead crane and hoist equipment is often purchased from:

- Used industrial machine brokers

- Equipment or heavy machine auctions

- Scrap or salvage yards

- Sites like Craigslist and eBay have third-party sellers.

What to look for when purchasing used overhead cranes

An equipment broker should either allow you to evaluate the overhead crane equipment on-site or employ a third-party specialist to do it on your behalf. You'll also want to choose a respected company that is honest and ethical, and can supply you with references or online reviews.

You should engage with a company that inspects and/or refurbishes the equipment they acquire on a regular basis before selling it. Although a broker may not be aware of the overhead crane's complete history or service life, they should be honest about its condition before selling it to you. You'll want to know what's in good working order, what's missing, and what needs to be replaced or repaired. Before purchasing overhead crane equipment, it's critical to understand the state of the overhead crane:

- What is the overhead crane system's age? It may not make financial sense to invest in an aging piece of equipment that will require frequent maintenance and repair if it is nearing the end of its service life.

- How frequently was the overhead crane system used? -You should try to gain an idea of the duty cycle or service categorization by analyzing how it was utilized and how often it was used, even if the broker doesn't have much information.

- Is it true that they're selling you all of the essential parts? -Are the trucks for the bridge, trolley, hoist, and end included? What type of electrical system does it have? Are runway and support beams available, or will a runway system have to be built?

- What kind of condition is the steel in if the runway and other structural supports are available? Is the runway a stand-alone system or one that connects to building supports?

- Is the system turned on?-Are all of the electrical and mechanical systems up to snuff?

- Is there a copy of the prior owner's maintenance records?-You'll want to know if the overhead crane system and components were frequently inspected and repaired in accordance with industry and manufacturer standards, much like you would when buying an used overhead crane.

If you want to buy an used overhead crane system, an equipment broker can be the best option. You may not be able to view or see the equipment prior to the sale at auctions, scrap yards, or internet vendors. They may also be unable or unwilling to provide you with information about the overhead crane's history and condition prior to the sale!

Comparison of used overhead cranes vs. new overhead travelling cranes

Purchasing an overhead travelling crane will undoubtedly increase productivity, increase output, and make overhead lifts more ergonomic and safer. If you're considering about purchasing a secondhand overhead travelling crane system, there are a few things you should investigate and consider before making a decision.

Price

There would be higher upfront charges if you purchase a new overhead crane from an overhead travelling crane manufacturer. You're paying for extra services such as engineering, material and component procurement, project management, fabrication, freight/delivery, installation, and the equipment's initial startup and load testing.

Most overhead travelling crane manufacturers, on the other hand, provide turnkey solutions and will oversee the project from start to finish. All or most of the services indicated above will be included in the project proposal when you receive a price from the manufacturer. If they aren't included in the manufacturer's proposal, you can ask them to add them or supply you with an estimate.

The initial expenditure on an used overhead crane will be significantly lower. However, you're simply saving money on the equipment and components themselves. There are a variety of different costs to consider, coordinate, and budget for, including:

- Components that are missing or don't work properly are repaired or replaced.

- Engineering analysis to determine proper duty cycle and service class of individual components and the entire system

- Structural survey to determine if your structure and/or foundation can support this overhead crane system

- Pickup and delivery of the overhead crane to your location

- Installation

- Inspection and/or testing of the overhead crane system before it is turned on

The actual issue with purchasing an used system is that you never know how much it will cost in the end. You'll have to factor in the expenses of further fabrication or modification to retrofit your equipment into your facility when you buy it. You'll also need to budget for additional costs such as surveying and maybe reinforcing your building's foundation and structural supports to accommodate a overhead crane system. Additionally, costs for replacing or repairing festooning and electrical panels, as well as the hoist and other mechanical components, can quickly pile up.

These additional fees can mount up to thousands, if not tens of thousands of dollars, and there's no guarantee that this overhead crane can meet your material handling needs.

Whether you purchase a new or used overhead crane system, you should be aware of some of the hidden costs associated with overhead crane ownership, such as:

- OSHA-mandated inspections

- Annual routine overhead crane maintenance

- Replacement overhead crane components and repairs

- Training for your overhead crane operators, riggers, and maintenance employees

Availability

It can take anywhere from 90 days to 12 months to design, source components, build, and install a new overhead travelling crane system, depending on the design and complexity of the overhead crane. When purchasing a new overhead travelling crane, you should anticipate devoting a large amount of time and effort to the following procedures:

- Initial consultations with overhead crane manufacturers;

- Gathering and comparing overhead crane quotes;

- Reviewing and modifying approval drawings;

- Delivery and installation preparation;

- Startup configuration and employee training

Fortunately, when you engage with a reputable overhead travelling crane manufacturer, they'll do a lot of the effort for you and guide you through the procedure step by step.

You'll have immediate access to the system you acquire when you buy an used overhead crane. However, you should anticipate to do a significant amount of the work yourself to get the system to your premises, installed, and operational. This could contain one or more of the following:

- Coordination of an engineering study and/or a structural survey of the overhead travelling crane equipment and your building

- Source missing systems or components and repair parts

- Arrange for overhead crane delivery and overhead crane installation

- Arrange for an initial overhead travelling crane inspection and overhead travelling load testing before start up

- Engineering and Duty Cycle

Choosing the appropriate overhead crane service class and duty cycle for an overhead travelling crane is critical for a customer attempting to balance the initial investment in a overhead crane system with the cost of future maintenance. When you purchase an used overhead crane, you are unlikely to have a clear picture of the application for which it was originally designed, as well as the specifications of the component systems.

If you buy a overhead crane that is under-specified for your lifting application, you will save money on the initial investment but will pay more in maintenance and downtime over the life of the overhead crane. If you purchase a system that was originally designed for a heavier-duty application, it may work to your advantage. You simply need to know how it was used, how frequently it was used, and how much service life is left on components such as brakes, motors, and drives.

Unfortunately, it is uncommon to buy an used overhead crane with a complete understanding of its history and specifications. Access to maintenance records, repair history, usage/operating time, and any upgrades or modifications made to the overhead crane or hoist equipment may be difficult or impossible.

You can commission an engineering study, in which you pay a third party to reverse engineer the overhead crane and its individual components. This can provide an estimate of the overhead crane's duty cycle as well as the remaining service life of electrical and mechanical components.

When you purchase a new overhead travelling crane system, engineers and estimators do all of the legwork to specify the most cost-effective and safest overhead crane design for your lifting application. Choosing the appropriate duty cycle or service class for an overhead travelling crane helps ensure that the overhead crane's components are durable enough to withstand the load and usage requirements throughout its service life.

The four most important requirements that a overhead crane manufacturer will use to determine the duty cycle for a new overhead travelling crane are as follows:

- Rated Load – An estimate of the loads lifted at or close to capacity.

- Service – Total hours in operation per day

- Number of Lifts – Average lifts and trolley and bridge movements made each hour

- Distance – Average length of each movement

Other factors that may not have a direct impact on overhead travelling crane classification but are taken into account when designing and specifying a new overhead travelling crane include:

- The overhead crane's speed – how quickly can it transfer materials or equipment? How many lifts can the overhead crane perform per hour?

- Maintenance needs – will the overhead crane need to be serviced on a regular basis, and how will maintenance or repair affect production and downtime?

- Operating environment – In what kind of environment or conditions will the overhead crane be used?

- Future requirements – Will there be any changes or increases in production requirements in the future? If you design a Class C overhead crane but anticipate lifting heavier loads or using your overhead crane more frequently in the future, you may need to consider a Class D range overhead crane.

Machine condition and reliability

Another important factor to consider when purchasing an used overhead crane is the condition of the equipment. If you can purchase from a reputable seller, they should allow you or a third party to come on-site and inspect the condition of their equipment before you buy.

Try to understand the environment from which the overhead crane is emerging. Was it sitting in a vacant building for an extended period of time and needs to be decommissioned? Was it disassembled and stored outside, where it was exposed to the elements? Is it in a storage or warehousing facility, for example?

A reputable seller or broker may even be able to connect it to power so you can inspect the electrical and mechanical systems. This will allow you to see how the motor and operator controls work, as well as give you an idea of any additional work that may be required to fully functional the system.

Look for any of the following signs of a faulty system, which could jeopardize overhead crane safety and reliability when in use:

- Hydraulic fluid or oil leaks

- Excessive corrosion or pitted metal

- Missing or broken parts

- Components that are seized or not moving freely

- Irregular welds on steel or mechanical pieces

- Bent or damaged beams

You should be aware that evaluating the condition of an used overhead crane system purchased from an auction, scrap yard, or online seller may be impossible. Many sellers will sell it "as is," with no post-sale support or troubleshooting.

When you purchase a new system from an overhead travelling crane manufacturer, you can expect all of the components to be brand new. The electrical system is properly grounded, and all electrical work is carried out in accordance with industry standards, using new and appropriately sized wires. All individual components will be brand new from the supplier, properly adjusted, lubricated, and warranty-backed. All runway, bridge, and structural beams will be made of new steel, will be properly aligned, will have a fresh coat of paint, and will be free of corrosion.

When you buy new from a reputable manufacturer, you'll also have the assurance that all work is covered by warranty and adheres to current industry regulations and standards.

Delivery, installation, and load testing

As previously stated, when you purchase an used overhead crane, you are responsible for coordinating a large portion of the logistics. You will almost certainly need to arrange for a flatbed to pick up the overhead crane system from the seller and transport it to your location.

You should also look for a reputable overhead crane dealer, local overhead crane service provider, or rigging or erection service company to assemble and install the overhead crane in your building. Once the system is in place and fully supported, you should have a full overhead crane inspection performed to ensure OSHA/ASME/CMAA compliance.

A qualified person must determine whether the conditions discovered during the inspection pose a hazard and whether a more thorough inspection is required. Any unsafe conditions discovered during the inspection must be corrected before the overhead crane can be used again. Only authorized personnel are permitted to make adjustments and repairs.

Any savings from purchasing used equipment could be put toward developing a comprehensive overhead crane inspection and preventative maintenance program. This can help to protect against catastrophic failures, equipment downtime, and ensure that your overhead crane is in compliance with industry regulations.

You'll need to have the overhead crane inspected and tested whether you acquire a new or secondhand overhead travelling crane. The overhead crane will need to be started up and load-tested when the upgrading work is done to ensure everything is in working condition. A third-party testing organization may be hired to do the test and assure that the overhead crane will function safely and efficiently. Prior to first use, your new overhead crane system must pass two operational tests and a rated load test, as required by OSHA 1910.179 Overhead & Gantry overhead cranes regulations:

- Testing of the hoist operation up and down; trolley travel; bridge travel; limit switches; and locking and safety devices

- Testing of the trip setting of the hoist limit switches to ensure the actuating mechanism of the limit switch is functioning properly

- Load test the overhead crane at no more than 125 percent of the rated load and keep test reports on file where they are easily accessible

- The overhead crane's load testing can be done with a certified weight from a load-testing business, or the known weight of a number of materials such as concrete, steel, or water weight bags.

- Warranty / Technical Support / Replacement Parts

When you purchase a new overhead travelling crane, you will receive the greatest level of after-sale service, support, and peace of mind. When you work with a reputed overhead crane manufacturer, all of the individual systems are tailored to the lifting application and come with a 5- to 10-year warranty in case any non-wearable system components fail.

There may be a limited 30-day guarantee on used overhead crane equipment, or no warranty at all. The majority of secondhand equipment is sold with the premise that the overhead crane will be delivered as-is, and any repairs or changes will be the buyer's burden.

With a new overhead crane, you'll get the manufacturer's complete support as well as any of the vendors they work with. There is normally a window after the sale and installation where the manufacturer can provide on-site support for troubleshooting, dialing in the controls and operation of your overhead crane, and training your personnel on how to utilize the new equipment.

If you buy secondhand overhead crane equipment, you'll be on your own to find a service provider that can troubleshoot problems and maybe stock repair parts in the event that something breaks down or wears out prematurely.

Another advantage of purchasing new is that current technology is more easily available and less expensive. There have never been more safety measures available for overhead travelling crane systems, and modern technology now allow for:

- Remote monitoring and diagnostic information for individual components

- Variable frequency drives to control the speed and motion of the overhead crane

- Radio controls

- Collision avoidance systems

- Brake slip detection

- Overload sensors and read-outs

One of the key benefits of purchasing a new overhead crane is that you receive fresh new components and a modern design. You know that if it needs to be maintained in the future, finding replacement parts through the manufacturer or one of their distributors will be easier and more cost-effective.

Electrical and mechanical replacement parts can become increasingly difficult to come by as a secondhand overhead crane system gets older. The original manufacturer may have gone out of business, lost its distribution network, or the parts may have become obsolete. If you can find the parts at all, they may have extremely long lead times and be very expensive.

Some overhead crane service businesses can reverse engineer or recreate outdated parts for older overhead crane systems, but this can be costly and time-consuming because these are often custom-designed and one-of-a-kind designs.

Which do you prefer, the used overhead crane or a new overhead crane?

You'll only get as much out of an overhead travelling crane as you put into it, whether you buy a new or used overhead crane. You should be able to get a reliable system that will boost production efficiencies if you do your homework, partner with a respected supplier, and understand how you'll be using it. You'll likely wind up with extra headaches and a potentially dangerous and troublesome overhead crane system if you buy just on the basis of price.

When choosing an overhead travelling crane firm to work with, keep in mind that price should never be the sole consideration. An overhead travelling crane system is a complex and important piece of machinery that helps your company increase efficiency and productivity. You should only work with a firm with whom you are completely comfortable and who you believe will deliver the finest service and value.

If you'd like to learn more about how an overhead travelling crane system may improve the efficiency and safety of your operation, or if you'd like to set up a consultation, contact a overhead crane specialist now.